In the world of material handling, the castor are ubiquitous and essential. Among the various materials available, Polypropylene (PP) wheel castors is different as one of the most common and widely used solutions across countless industries. Their popularity is no accident; it's a result of a perfect balance of durability, cost-effectiveness, and versatility. But not all PP castors are created equal. Understanding the nuances of their construction is key to selecting the perfect caster for your application.

As a China caster manufacturer and supplier, we provide a comprehensive range of high-quality PP castors designed to meet diverse needs. Let's break down what makes our PP castors a top choice.

Bearing Type comparison: A Quick Guide

The bearing is the core component that defines a castor's performance, especially its load capacity and ease of movement. Our PP wheels are available with three primary bearing types:

1. Plain Bearing (Bush Bearing):

Characteristics: Features a simple sleeve design, often made from steel Bushing and plastic pp wheel. This offers a cost-effective solution for low-speed, low-frequency applications.

Load Capacity: Good for light to medium-duty loads.

Application & Moving: Ideal for lightweight trolleys, furniture, and equipment that requires occasional movement rather than constant rolling. It provides a rigid ride.

Price: The most economical option.

- 2. Single Precision Ball Bearing:

Characteristics: Incorporates a single precision ball bearings. This design significantly reduces rolling resistance compared to plain bearings.

Load Capacity: Excellent for medium-duty applications.

Application & Moving: The perfect choice for applications requiring frequent, easy movement with a smoother roll. Think of workshop carts, restaurant equipment, and institutional trolleys.

Price: A mid-range option offering great value for the performance.

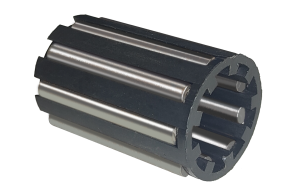

3. Roller Bearing (Needle Bearing):

Characteristics: Utilizes cylindrical rollers, providing a larger contact area within the raceway. This makes them exceptionally robust and capable of handling heavier radial loads.

Load Capacity: Designed for heavy-duty and high-capacity applications.

Application & Moving: The go-to for industrial environments where heavy loads are moved regularly. They offer superior performance under stress with a very smooth roll.

Price: A premium bearing option for demanding tasks.

Mobility and Control: Selecting the Bracket Type

The bracket, or horn, determines how the castor is mounted and functions. We offer a full spectrum to suit any requirement:

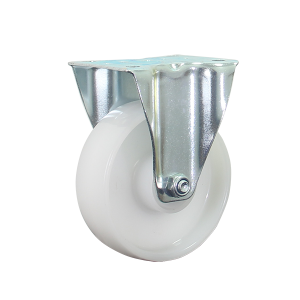

Fixed Bracket

For straightforward, linear movement. The wheel does not swivel.

Swivel Bracket

Provides 360-degree maneuverability, essential for navigating tight corners and aisles.

Swivel with Total Brake

Offers maximum control. The total brake function simultaneously locks both the wheel's rotation and the swivel movement, ensuring complete stability for loading and safety.

PP vs. PA (Nylon): Knowing the Difference

At a glance, it can be incredibly difficult to distinguish between PP and PA (Nylon) wheels. However, their material properties are quite different, impacting their ideal use cases.

PP (Polypropylene) Castors:

Economical: Generally more cost-effective than nylon.

Chemical Resistance: Excellent resistance to a wide range of acids, alkalis, and solvents.

Non-Marking: PP wheels are typically non-marking, making them perfect for protecting delicate floor surfaces like vinyl and epoxy.

Moisture Resistance: They are impervious to moisture and will not rust or corrode.

Load & Temperature: Suitable for light to medium loads and have a lower maximum operating temperature than nylon.

PA (Nylon) Castors:

Durability & Load Capacity: Nylon is a harder, more rigid material, offering higher load capacities and better resistance to abrasion and wear from rough surfaces.

Temperature Resistance: Can withstand higher temperatures than PP.

Application: Nylon castors are extensively applied in material handling settings that demand high load capacity and constant mobility, including industrial shelving systems and logistics machinery.

Choosing the right trolley wheel material is crucial. For most indoor, light to medium-duty applications on sensitive floors, PP is the ideal choice. For heavier loads, rougher terrain, or high-temperature environments, a nylon castor or other PA option might be the better fit.

Why Choose Us as Your Caster Supplier?

As a trusted China caster supplier, we are committed to providing Precision Casters that meet the highest standards of quality and reliability. Whether you need robust wheels for trolleys in a warehouse, non-marking plastic wheels for trolleys in a hospital, or a secure trolly wheel with brake for a retail cart, we have the solution.

Our expertise as a China caster manufacturer allows us to control every step of the production process, ensuring you receive durable, high-performance castors at a competitive price. Explore our full catalog to find the perfect PP castor to keep your world moving.

Post time: Sep-06-2025